Single Service

For our customers, Pearce delivers a single source for castings, machining, fabricating and repairs as needed. Pearce engineers assist in industrial design and work with various industries to develop product lines by providing the following services:

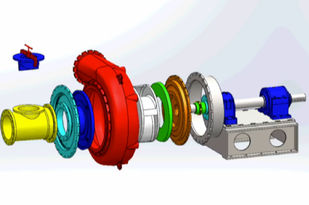

3-D Modeling & SolidificationPearce Utilizes the technology of solidification software to optimize yield and riser placement and to detect possible shrinkage and porosity. This software is excellent for new castings, troubled parts, and changes to existing parts. Pearce also contracts with three consulting metallurgists to help design metal specifically for customer applications. |

Pattern ShopPearce has a full service pattern shop with personnel experienced in building, repairing, or modifying existing patterns. With over 40,000 sqft of pattern storage facilities, Pearce can store your active pattern in an insured, concrete, facility with a sprinkler system installed for your pattern’s protection. |

Heat TreatingPearce has four in-house heat treat ovens to optimize our casting quality and to meet your metal specifications. Using our controlled and monitored systems, we can become your one source for casting needs. |

Machine ShopPearce has a full service pattern shop with personnel experienced in building, repairing, or modifying existing patterns. With over 40,000 sqft of pattern storage facilities, Pearce can store your active pattern in an insured, concrete, facility with a sprinkler system installed for your pattern’s protection. |

InventoryPearce keeps on-site inventory to give our customers the added security of having parts readily available when needed. To shorten customer lead times, Pearce stocks finished parts inventory and consignment inventory throughout the U.S. |

DeliveryPearce knows delivery is crucial, so we employ two full service tractor trailers to expedite delivery to your facility. Pearce is dedicated to delivering quality products on time, every time. |

Serving Industry

With the Pearce Group’s ability to pour castings from 20-12,000 pounds, we may be the exact solution to fit your needs. The following is a partial list of applications where you will find Pearce castings:

Industrial

Oil and Gas

- Draw Works Parts

- Frac Sand Equipment Parts

- Offshore Applications

- Tools and Equipment Parts

Pulp and Paper

- Chain Ladders

- Crushing and Grinding

- Cyclone Separators

- Fines Recovery Systems

- Elbows

- Hammer Mill Parts

- Pulverizing and Shredding

- Mill Crushers-Tires and Components

- Aftermarket Replacement Parts

Energy and Power Generation

- Boiler Shoes

- Pet Coke

- Tube Supports

- Tuyeres

Dredging and Mining

Complete Pumps and Replacement Parts

- Bearing Housing

- Boosters

- Compressor Components

- Hopper and Tank Systems

- Impellers, Cases, and Liners

- Mus Pump Parts

- Power Units

Concrete and Aggregate

- Concrete Clinkers

- Cyclones

- Elbows

- Fine and Course Material Washers

- Fine Recovery

- Hammer Mill Parts

- Impact Crusher Parts

- Log Washers

- Material Handling and Transfer Systems

- Processing Equipment

- Pug Mills

- Pulverizing Equipment

- Rolling Mills

- Slurry Systems

Additional Applications

Aftermarket Replacement Parts Test

- Corrosive Services

- High Water Services

- Large Mobil Equipment Parts

- Parts for Bridge Building and Repair

- Replacement for Fabricated Parts

- Replacement of High Breakage Items Test